![]()

THE SOLUTION

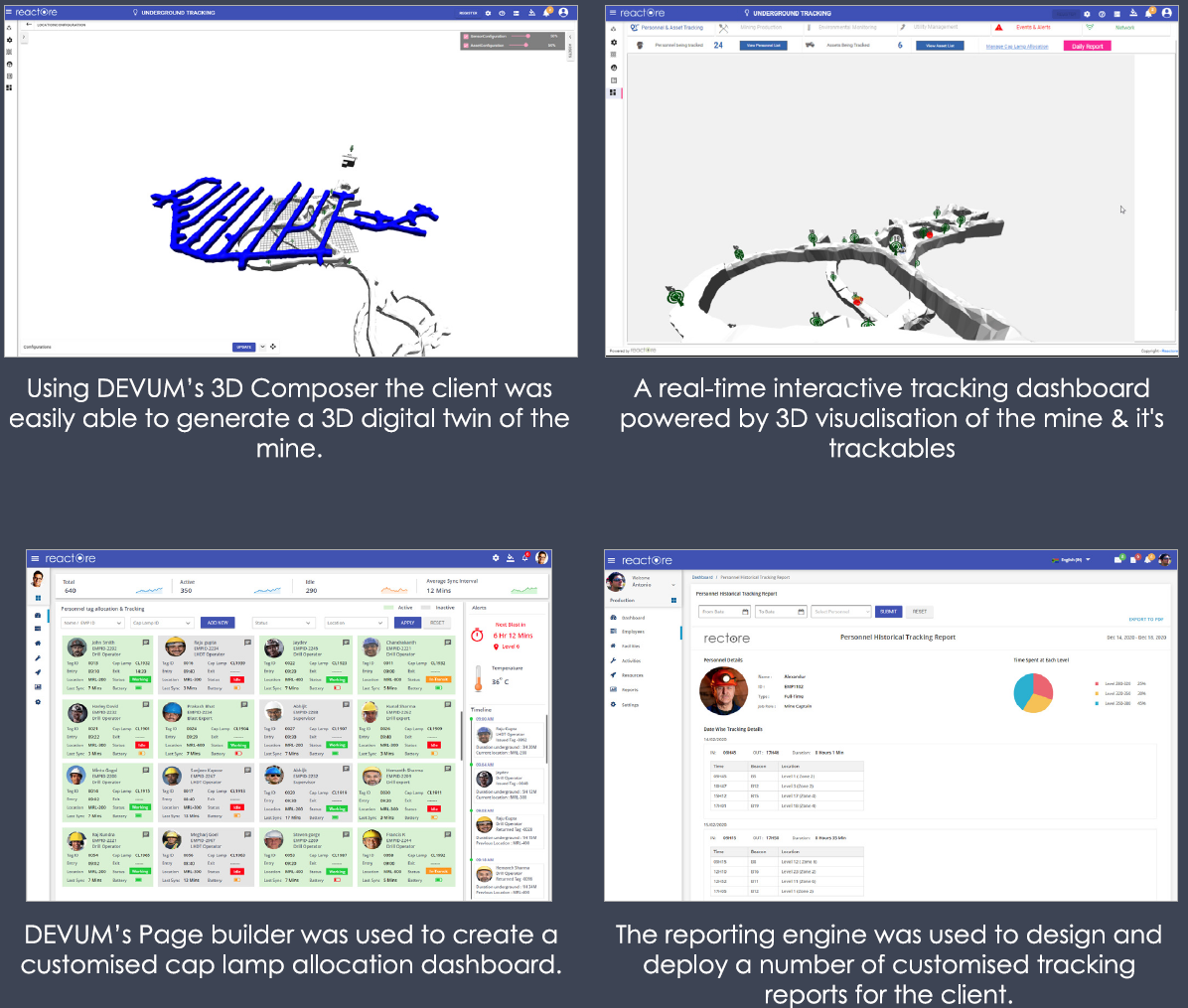

Real-time tracking of both personnel and equipment for an underground mining operation - visualised as a 3D digital twin for remote monitoring from the surface.

Real-time tracking of both personnel and equipment for an underground mining operation. The location of the personnel & equipment was displayed on an interactive isometric 3D dashboard and their movement was visualised in real-time. The dashboard was monitored by control room operators in a surface location at the mine and at the corporate head offices, remotely. The solution was achieved by integrating with the specialised tracking sensors provided by the DEVUM channel partner.

CLIENT

The end user was a large multinational gold mining group with key operations situated in Eastern Europe. The group embarked on a progressive digitalisation journey with a DEVUM channel partner who utilised our software platform to augment their existing hardware and sensors as part of a larger digitalisation solution. Our partner now relies on DEVUM as their go-to platform of choice to enhance their existing technology portfolio.

THE PROBLEM STATEMENT

SAFETY

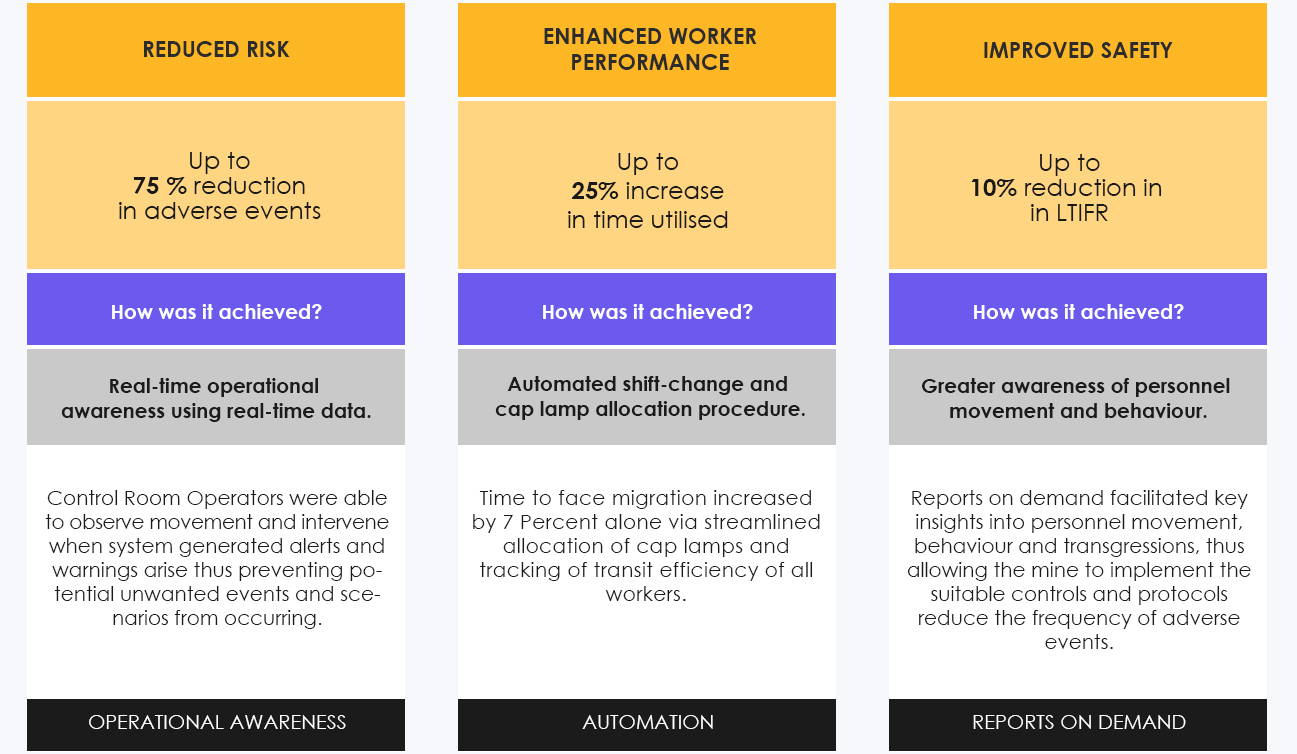

There were ever-present safety concerns due to a lack of real-time awareness of personnel and equipment location underground at any given time at the mine.

DEVUM’s workflow engine allowed for exception alerts to be generated based on the mine-defined business rules.

SCOPE OF OPERATION

With Over 750 personnel and 100 equipment requiring tracking across kilometres of underground tunnels, managing the operation using traditional/manual means was not ideal and often ineffective.

The DEVUM PLATFORM was scalable and allowed for additional assets and personnel to be incorporated into the tracking solution, seamlessly.

LACK OF AUTOMATION

The process of allocation of Cap Lamps and safety equipment to workers was time-consuming and inefficient resulting in a significant reduction in available production hours.

PAGE BUILDER & FLUENT SERVICES was used to produce a Cap Lamp and safety gear allocation screen to streamline and automate the issuing of equipment to personnel

PERSONNEL EFFICIENCY

Transit efficiency and productive time at the mining face were not optimal due to a lack of situational awareness of personnel transit data and time utilization.

KPI BUILDER was used to create performance management benchmarks and KPI’s to track the key metrics associated with personnel transit time and efficiency, in real-time.

INFOGRAPHIC

SCREENSHOTS

BUSINESS VALUE

Like what you see?

We have some great templates similar to this solution available for you to kick-start your journey.

Still undecided?

Check out our FAQ and Evaluation Guide for more info.

Alternatively, you can contact us at info@devum.com or contact one of our friendly consultants to assist you further.